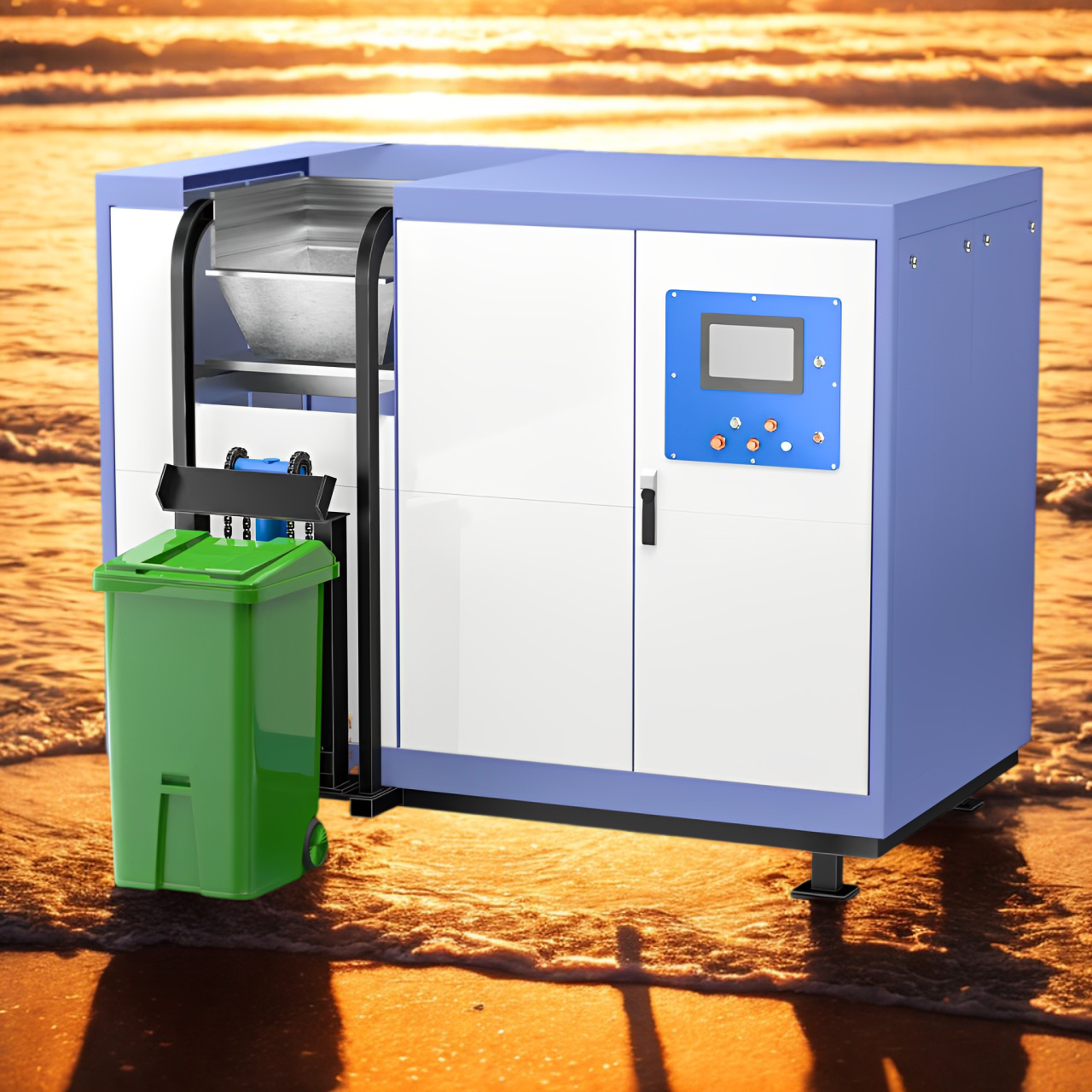

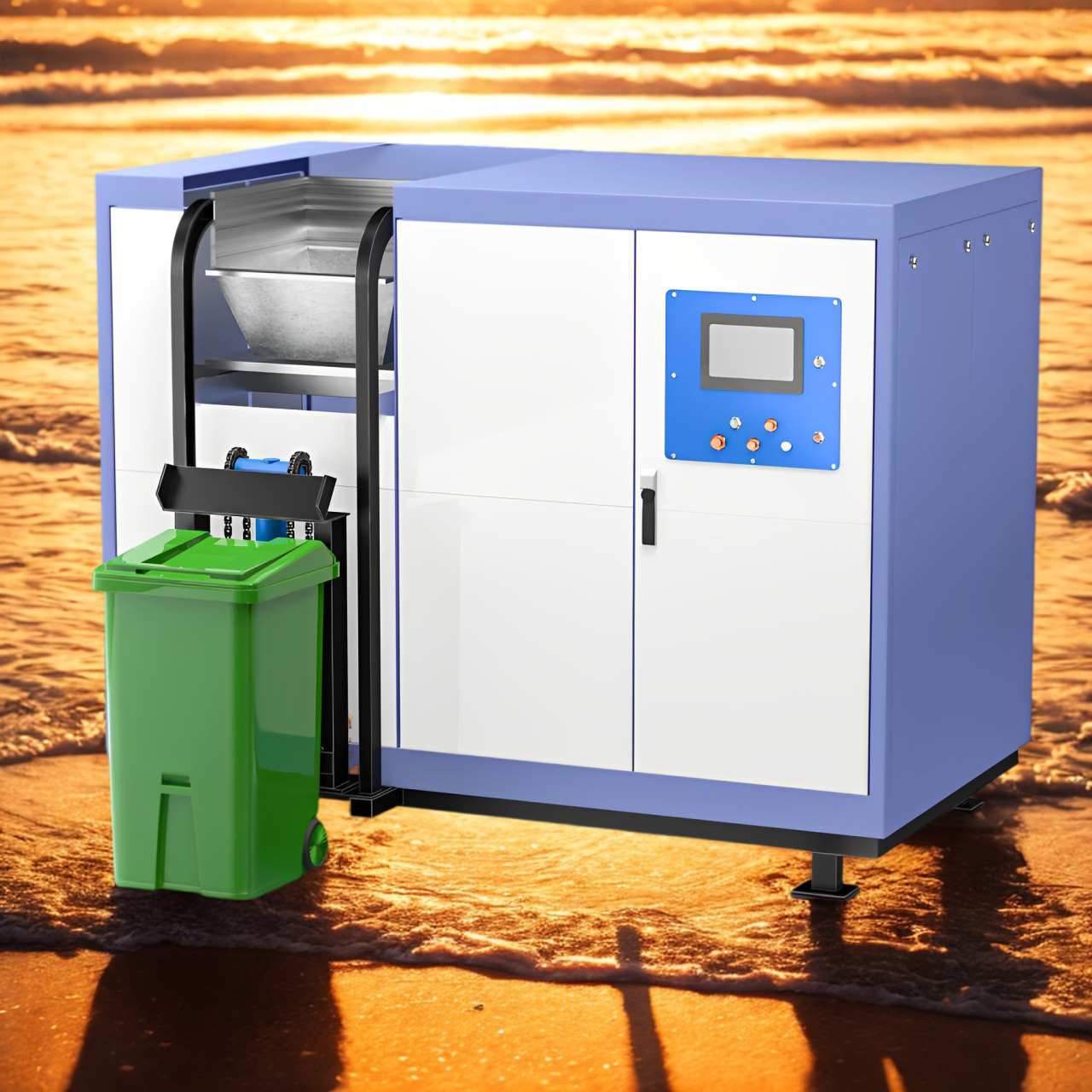

fermentation composting machine factory

A fermentation composting machine factory represents a state-of-the-art facility dedicated to manufacturing advanced waste processing equipment. These facilities specialize in producing machines that transform organic waste into valuable compost through controlled fermentation processes. The factory integrates cutting-edge automation systems with precision engineering to create efficient, reliable, and environmentally conscious composting solutions. The production line encompasses various stages, from raw material processing to final assembly, ensuring each machine meets strict quality standards. The facility's core focus lies in developing systems that accelerate the natural decomposition process while maintaining optimal temperature, moisture, and oxygen levels throughout the fermentation cycle. These machines are designed to handle diverse organic waste streams, including food waste, agricultural residues, and organic industrial byproducts. The factory employs advanced quality control measures and testing procedures to guarantee the durability and performance of each unit. With integrated smart monitoring systems, the machines produced offer real-time data tracking and automated parameter adjustment capabilities. The facility also maintains dedicated research and development departments to continuously improve product efficiency and incorporate innovative technologies.